From towering skyscrapers to remote bridge installations, construction cranes are engineered for lifting, moving, and placing heavy materials on a variety of job sites. Depending on terrain, job scope, and weight requirements, different cranes offer unique advantages.

At Heavy Equipment Colleges of America (HEC), we specialize in training up-and-coming heavy equipment operators on the ins and outs of crane functions. In this guide, we’ll explore the most common types of construction cranes, categorized into mobile and fixed/static options.

Build a Strong Future in Heavy Equipment Operation

Train to Operate Tower Cranes Safely and Confidently

Real-World Experience | Expert Instructors | Career-Focused Training

Enroll in Our Crane Operator Program Today!

Start Enrollment ProcessFind The Right Location For YouMobile Cranes vs. Fixed or Static Cranes

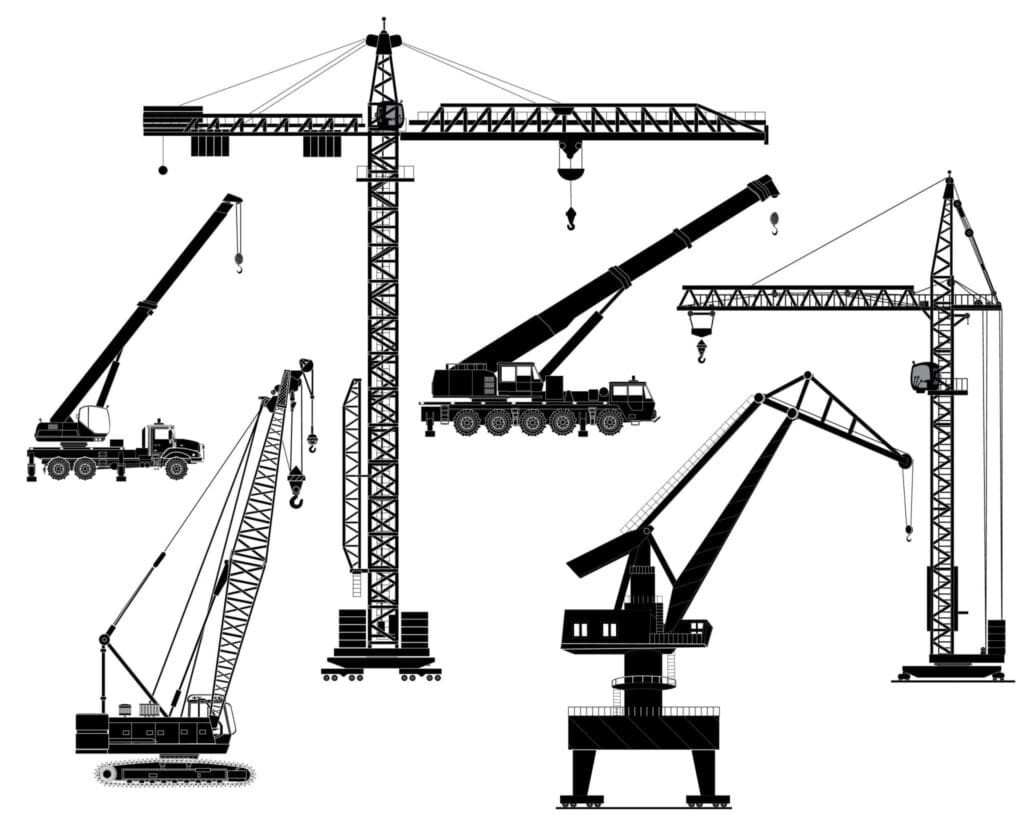

Every job site requires a specific crane that’s designed to take care of the job safely. With so many options to choose from, this wide range of construction cranes is generally divided into two major groups:

- Mobile Cranes: Mounted on wheels, tracks, or other transportable platforms, these cranes are designed to move around the job site or from one site to another. They offer flexibility, quick setup, and are often used for short-term or multi-location projects.

- Fixed or Static Cranes: Installed in a permanent or semi-permanent location, these cranes provide maximum lifting capacity and vertical reach. They’re ideal for high-rise building projects or situations where mobility isn’t needed.

Types of Mobile Cranes

Mobile cranes are known for their versatility and ability to move across job sites with minimal setup. They also come in a variety of designs to suit different construction challenges. Below are the most common types used across the industry, each with its own specialized purpose.

Crawler Cranes

Crawler cranes are large, heavy-duty machines equipped with tracks instead of wheels, making them ideal for soft or uneven terrain. They’re powered by a lattice boom, which is a long, truss-like structure that provides stability and reach without excessive weight.

These cranes are often used for large-scale infrastructure projects, such as wind farms, bridges, and industrial plants. Since they don’t need outriggers for stability, they can lift extremely heavy loads without additional support.

Carry-Deck Cranes

Compact and highly maneuverable, carry-deck cranes are perfect for lifting and transporting materials around tight job sites. Their rotating boom sits on a flat, deck-like surface, allowing for materials to be placed or carried on board.

Carry-deck cranes offer 360-degree rotation and are simple to set up, making them popular in warehouses and maintenance facilities.

Rough-Terrain Cranes

Rough-terrain cranes are built specifically for off-road job sites. Equipped with oversized tires and four-wheel drive, they’re ideal for construction zones where pavement is limited or nonexistent.

These cranes feature a telescopic boom mounted on a short, rugged undercarriage. Although they’re not designed for highway travel, rough-terrain cranes offer powerful lifting capabilities and stability, thanks to outriggers that keep the crane level and balanced.

Truck-Mounted Cranes

Truck-mounted cranes combine lifting power with easy highway mobility. These cranes are fitted to the back of a standard commercial truck and feature a hydraulic boom arm that extends to lift loads at various distances.

Their mobility makes them a go-to choice for short-term lifts or jobs that require frequent relocation. Truck cranes strike a balance between convenience and lifting capacity.

All-Terrain Cranes

All-terrain cranes merge the best features of truck-mounted and rough-terrain cranes. Designed for both road travel and rugged site access, these cranes can drive at high speeds on highways while still performing effectively on difficult surfaces.

They come with multiple axles, all-wheel steering, and telescopic booms, making them adaptable to a wide range of environments without sacrificing capacity.

Floating Cranes

Floating cranes, also known as crane vessels or crane ships, are mounted on barges and used for marine construction. These are essential for lifting heavy equipment onto ships, building offshore platforms, or supporting bridge construction over waterways.

Because they operate on water, floating cranes are specially engineered to remain stable despite waves, currents, or tides.

Railroad Cranes

Designed to travel on train tracks, railroad cranes are used for maintaining rail systems and lifting heavy rail components. They often come into play during track repairs, derailment recoveries, or rail construction.

Though their use is specialized, railroad cranes are critical to keeping national rail systems functioning safely and efficiently.

Aerial Cranes

Also known as sky cranes or helicopter cranes, these are used to lift and transport loads to locations inaccessible by land. While limited in load capacity, they provide an unmatched advantage when terrain or access routes are a challenge.

These airborne cranes offer flexibility where ground cranes simply can’t go.

Types of Fixed/Static Cranes

Fixed or static cranes are built to stay in one location throughout a construction project. These cranes are known for their strength, stability, and ability to lift heavy materials to great heights.

They’re commonly used in long-term or high-rise construction where mobility isn’t necessary. Below are some of the most widely used types of fixed cranes.

Tower Cranes

Tower cranes are the most recognized cranes on major construction sites. They’re tall, stationary cranes with exceptional vertical reach, often used to lift steel, concrete, and large tools several stories high. These construction cranes are anchored to concrete slabs to ensure stability and balance.

The main types of tower cranes include hammerhead cranes, level luffing cranes, flat-top cranes, and self-erecting cranes.

Hammerhead Cranes

A subtype of tower crane, hammerhead cranes have a horizontal arm that remains stationary while the trolley moves along the jib to lift and place materials. These cranes are well-suited for repetitive lifting in fixed directions.

Their straightforward design and precision movement make them a staple in urban construction zones.

Level Luffing Cranes

These cranes are designed so that the hook remains at a constant level as the jib/arm moves in and out. This allows for precise horizontal positioning of loads without adjusting vertical height.

Level-luffing cranes are essential in environments where spatial precision is more important than height.

Self-Erecting Cranes

Self-erecting tower cranes are ideal for small- to mid-size projects where rapid deployment is needed. These cranes can be assembled quickly without large teams or external equipment.

Their efficient design makes them cost-effective and perfect for short-duration construction jobs.

Overhead/Bridge Cranes & Gantry Cranes

These types of construction cranes are commonly found in factories and warehouses. Overhead cranes, also called bridge cranes, operate along ceiling-mounted tracks. In comparison, gantry cranes have freestanding legs.

Both of these types of construction cranes allow for safe, controlled movement of large loads in tight indoor spaces.

Jib Cranes

Jib cranes feature a horizontal arm (jib) that supports a movable hoist. They are commonly wall- or floor-mounted and used in repetitive manufacturing processes.

Though limited in range and capacity, jib cranes are efficient and space-saving. They can maneuver through tight spaces and safely transport materials to where they need to go.

Stacker Crane

Stacker cranes are used in automated storage and retrieval systems. They run on tracks and are often fully automated, making them ideal for warehouse environments.

These cranes are designed to store and retrieve larger items such as shipping containers and other industrial storage containers. This machinery helps improve overall warehouse efficiency.

How To Choose the Right Crane for Construction?

Choosing the right type of construction crane depends on the specifics of your project. Before you decide which crane is right for the job site, consider the following factors:

- Load Capacity: How heavy are the materials you need to lift?

- Reach and Height: What vertical and horizontal distances must the crane cover?

- Terrain Conditions: Is the job site paved, uneven, or over water?

- Mobility Needs: Will the crane stay in one place or move between sites?

- Space Constraints: Are there overhead obstructions or limited ground space?

For example, tower cranes are great for vertical reach in tight downtown construction zones, while rough-terrain cranes are perfect for off-road access in remote areas.

Understanding each crane’s capabilities ensures the safest and most efficient operation, saving time and money while avoiding downtime.

Get Credited as a Crane Operator with HEC

Interested in working with any of the types of construction cranes listed above? The first step is professional training, and Heavy Equipment Colleges of America (HEC) is a trusted place to start.

Our faculty and staff offer nationally recognized, hands-on programs for new and experienced operators, including:

- Mobile Crane Operation

- Tower Crane Certification

- Lattice Boom Crane

- Fixed Cab Crane Operation Program

- And More!

HEC helps you get certified, get trained, and get on-site faster with programs tailored to real-world job conditions and employer needs. If you’re ready to launch your career in crane operation, there’s no better time than now.

Explore all our available programs to find the one that’s right for you. When you’re ready, apply online to start your path toward certification.

Start Your Crane Operator Career With Confidence

Kickstart Your Crane Operator Journey Today!

Hands-On Training | OSHA-Compliant Courses | Job-Ready Skills

Become a Certified Tower Crane Operator Today!

Start Enrollment ProcessFind The Right Location For You