On a construction site, you have a variety of heavy machinery and equipment that help you get the job done quickly and safely. A common tool you’ll find on a site is a backhoe loader, which are massive excavators that move materials around and dig holes or trenches. These massive machines are a significant investment, and you want to make sure it’s working properly so they can get the job done.

Before you start digging a hole, you’ll need to perform a backhoe loader inspection. This simple step keeps yourself and others safe on the job site while ensuring the equipment is working properly without any issues.

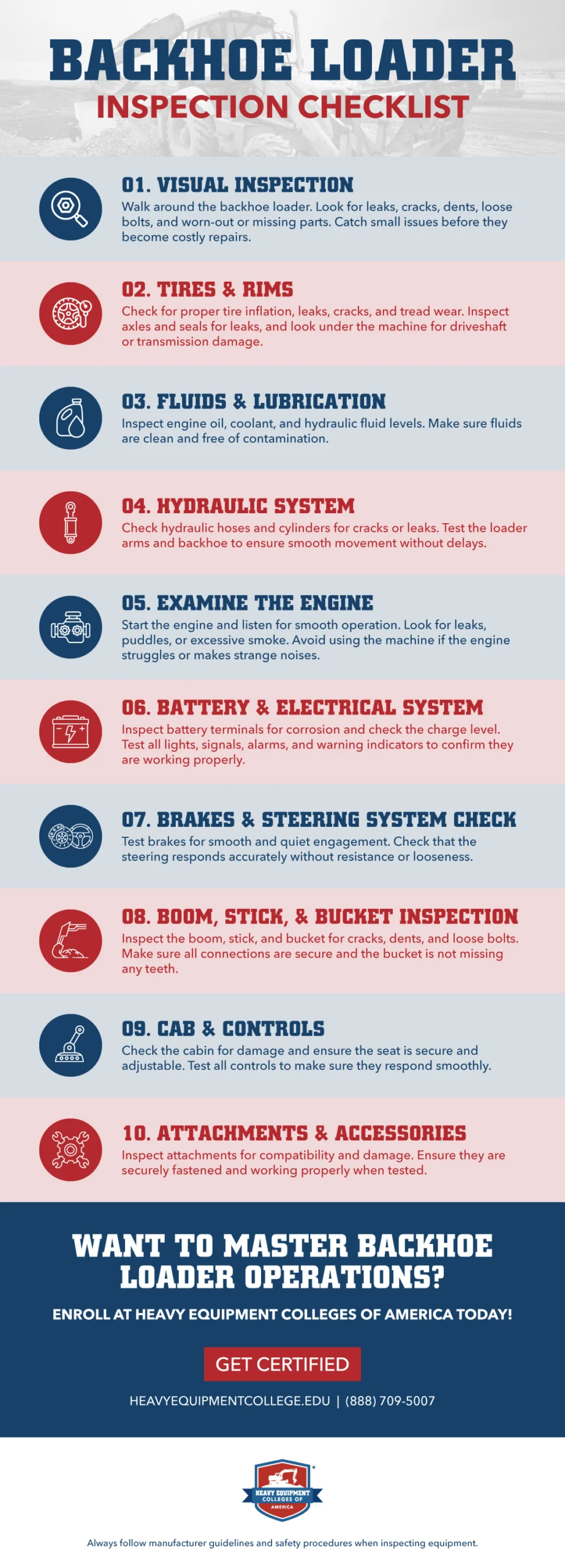

Our team at Heavy Equipment Colleges of America is here to offer guidance on what to look for during an inspection. We’ve created this handy dandy checklist you can use to perform an extensive backhoe loader inspection before you get to work.

Table of Contents

Backhoe Loader Inspection Checklist

When inspecting heavy machinery, you want to be thorough and take your time. Rushing the process or skipping a step to save time can have dire consequences and lead to equipment failure. Here are 10 easy steps to make sure you hit the primary components of a backhoe loader inspection and don’t miss a thing:

1. Visual Inspection:

The first step of an extensive inspection is to walk around and give it a visual lookover. Take a lap around the backhoe loader and check for any visible damage or issues. Keep an eye out for visible wear and tear, such as leaks, cracks, or dents.

These minor things are more than cosmetic, and they can develop into serious problems if not addressed properly. It’s better to catch them early and get them taken care of than wait until they become more catastrophic.

In addition to visible wear and tear, check for loose bolts, worn-out parts, or missing components that can impact the equipment’s safety and performance. Make sure these issues are noted and addressed before you start using the equipment.

2. Tires and Rims

While you’re looking, check the tires on the backhoe loader. Make sure the tires are properly inflated and there aren’t any leaks or damage. You can also get under the equipment and take a look at the axles. Check the seals for any leaks, and make sure there isn’t any visible damage from rough terrain.

While you’re under there, you can also peek at the driveshaft. Bumpy terrain and rocks can damage the driveshaft or transmission, so look for any obvious signs of wear and tear. Look for signs of leaks on the ground near the machine and make sure the transmission and driveshaft look good.

3. Fluids and Lubrication

Three main fluids improve the overall performance and efficiency of a backhoe loader: engine oil, coolant, and hydraulic fluids. Each of these plays a specific role and ensures your equipment is working properly.

Take a look at the engine oil. Make sure the oil levels look good and the oil is clear. If it looks dark or cloudy with particles, it may be time to change the oil. This keeps the engine running smoothly.

Coolant keeps the system from overheating as you work. Make sure there’s enough coolant in the system and that it looks clean. Cloudy or contaminated coolant can cause the system to overheat.

Hydraulic fluids lubricate the hydraulic system so the backhoe loader can move properly. Check that the fluid levels look good and the fluid is free of contaminants.

Dig Into a New Career!

Enroll in Our Backhoe Loader Training Program Today!

Accelerated Programs | Multiple Locations | Job Placement Help

Open The Door To A New Career!

Start Enrollment ProcessFind The Right Location For You4. Hydraulic System

The hydraulic system powers the backhoe, loader arms, and any other attachments on the equipment. Take a look at the hydraulic hoses that carry the hydraulic fluids throughout the system. Cracks and other damage can cause a fluid leak, and this can decrease the equipment’s performance.

If there aren’t any leaks, you can run a quick test of the hydraulic system to see if everything is working as it should. Move the loader arms and backhoe and see if they move smoothly without delays. Jerky, slow movements from the arms can indicate a problem with the hydraulic system.

5. Examine the Engine

The engine is the heart of your backhoe loader, and the machine can’t run without it. Turn on the engine and listen to how it starts up. It should kick into gear with no problems or stutters. An engine that struggles to start or clunks to life may have hidden issues. See if you find any signs of oil or coolant leaks, such as puddles on the ground near the base of the machine.

Also, make sure no smoke billows from the engine during startup. A small plume of smoke during startup when it’s cold outside can be normal, but excessive smoke is cause for concern.

6. Battery and Electrical System

The battery supports the engine and powers the lights and signals on the equipment. Check for signs of corrosion in the battery terminals and carefully clean them out if necessary. You can also look at the battery’s charge level and make sure it’s within the proper safety range for equipment operations.

Once the battery is good to go, inspect the headlights, taillights, turn signals, and brake lights. Make sure all alarms and warning lights are working properly.

7. Brakes and Steering System Check

Brakes and steering are vital in ensuring equipment performance and safety. Malfunctioning brakes can lead to a serious accident that causes property damage and personal injuries. Before driving the backhoe loader, engage the brakes and listen. They should engage smoothly without any clicks or loud noises. Wear and tear over time can lead to soft, spongy brakes that will need replacements.

While you’re in the cabin, leave the loader parked and engage the steering system. The tires should respond quickly and smoothly, and there shouldn’t be any resistance or pulling from the controls. If the steering feels loose or unresponsive, this needs to be addressed before you can use the backhoe loader.

8. Boom, Stick, and Bucket Inspection

Similar to the general visual inspection, you’re going to want to take a closer look at the boom, stick, and bucket of the backhoe loader. Carefully inspect all three components for any cracks, bends, dents, or other damage. Check that there aren’t any missing bolts, and the connections look secure. Make sure the bucket isn’t missing any teeth or bolts.

9. Cab and Controls

Hop into the cabin and look for visible signs of wear and tear. Make sure the seat is properly secured and adjustable, and there are no cracks or damage to the inside of the cabin. Take a seat and operate the controls to make sure the system is responsive and smooth. Do not operate the backhoe loader if the controls are sluggish or unresponsive.

10. Attachments and Accessories

Backhoe loaders come with various attachments you can swap out depending on the task at hand. From forks to rippers, make sure that every attachment is compatible with the backhoe loader and doesn’t show signs of serious wear and tear. You should also test them with the machine to make sure they work properly without any issues.

To Recap

A thorough inspection of any construction equipment prevents job site accidents and improves overall work efficiency. You don’t want to rush the process or skip steps, as one missed issue can quickly become catastrophic. From checking the headlights to inspecting the brakes, you should look at each part of the equipment to check for any potential damage or problems.

This backhoe loader inspection checklist can help you make sure your equipment is ready to go before you get to work, keeping yourself and others on the job site safe.

Get Backhoe Loader Training with Heavy Equipment College

At Heavy Equipment Colleges of America (HEC), we strive to provide students with extensive training and real-life experience to set them up for success in the world of heavy equipment operations.

We offer backhoe loader certification programs that set you above other candidates in the job market. In just as little as 3 weeks, you can complete our backhoe and OSHA training courses and be on your way to joining the workforce. Apply today to take the first step towards a successful and rewarding career as a heavy equipment operator.

Your Future in Heavy Equipment Starts Here!

Get Certified. Get Hired.

Get Started with HEC!

Accelerated Programs | Multiple Locations | Job Placement Help

Open The Door To A New Career!

Start Enrollment ProcessFind The Right Location For You